Company

Research & Development

Constantly seeking new possibilities to improve our toilet seats, making them even more comfortable, easier to clean and assemble, is our permanent goal, this maintaining the high quality and environmental friendly commitment.

All new projects and ideas are projected with up to date software and equipments by our designer team.

Tooling

In our workshop we make ideas come true. Here we manufacture moulds and prototypes using CNC machinery and 3D printers. Creating concepts through prototype milling or 3D printing is a powerful tool in the validation process.

CNC machinery together with a well experienced team can accommodate all client’s requests, creating lifelong tools.

Planning

We like to look at our planning department as the essence of our company because we know good quality products must be delivered on time.

A state of the art management software monitored by our meticulous team, allows us to control all the functionality of our company in real time.

Production

Our factory is a living being, pulling 24/7. A well-equipped machine park provides a daily mass production of toilet seats. Industry 4.0 is here and we are taking huge steps to keep up. Handling and finishing are almost without human influence, allowing efficient results, with minimum human effort.

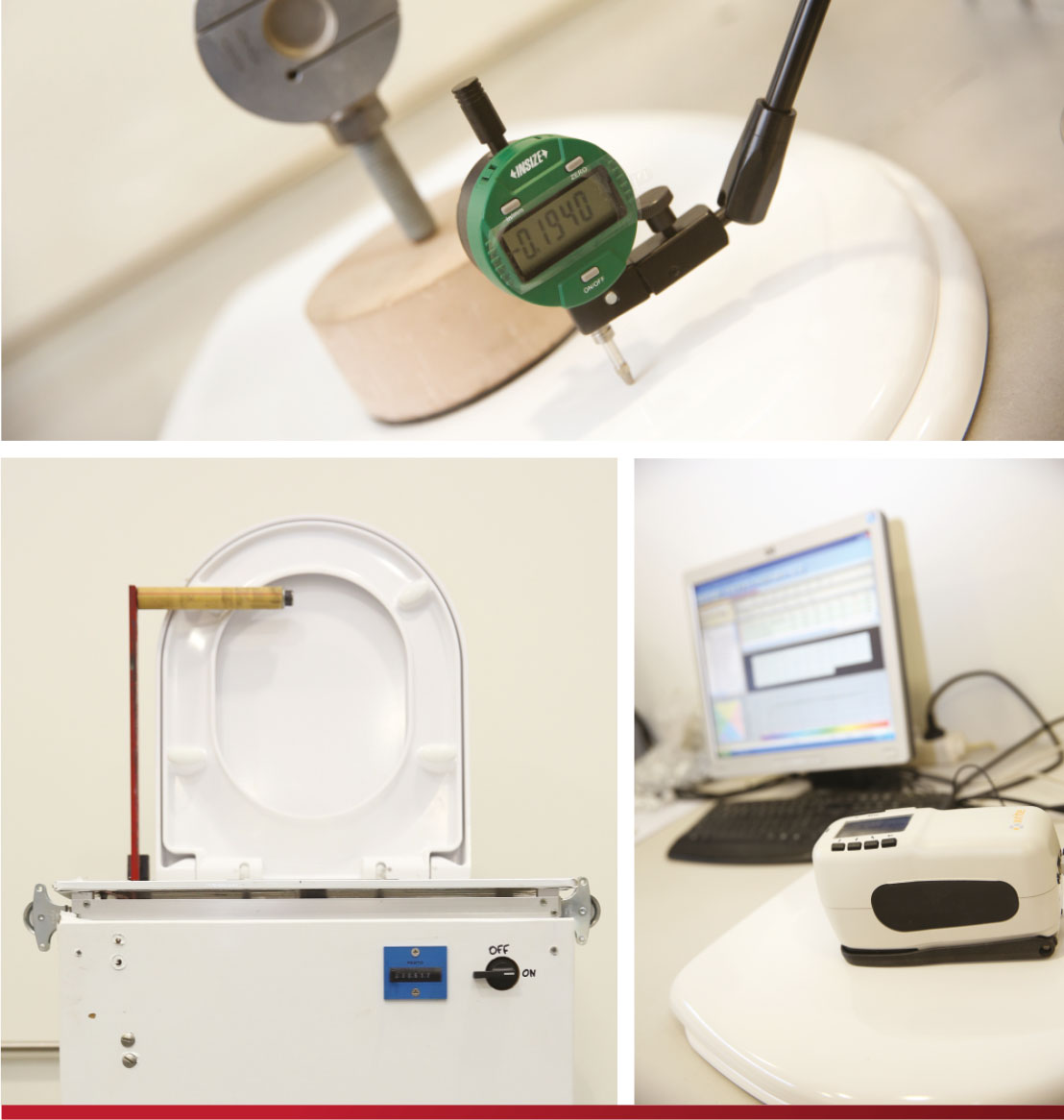

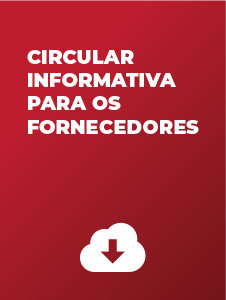

Quality & Environment

JBMC has a certified quality and environment management systems according to the normative references ISO9001:2015 and ISO14000:2015. The toilet seats production is also certified according to NF240 standards.

The certification guarantees our customers the quality and services of our products, as well as a continuous improvement of the organization.